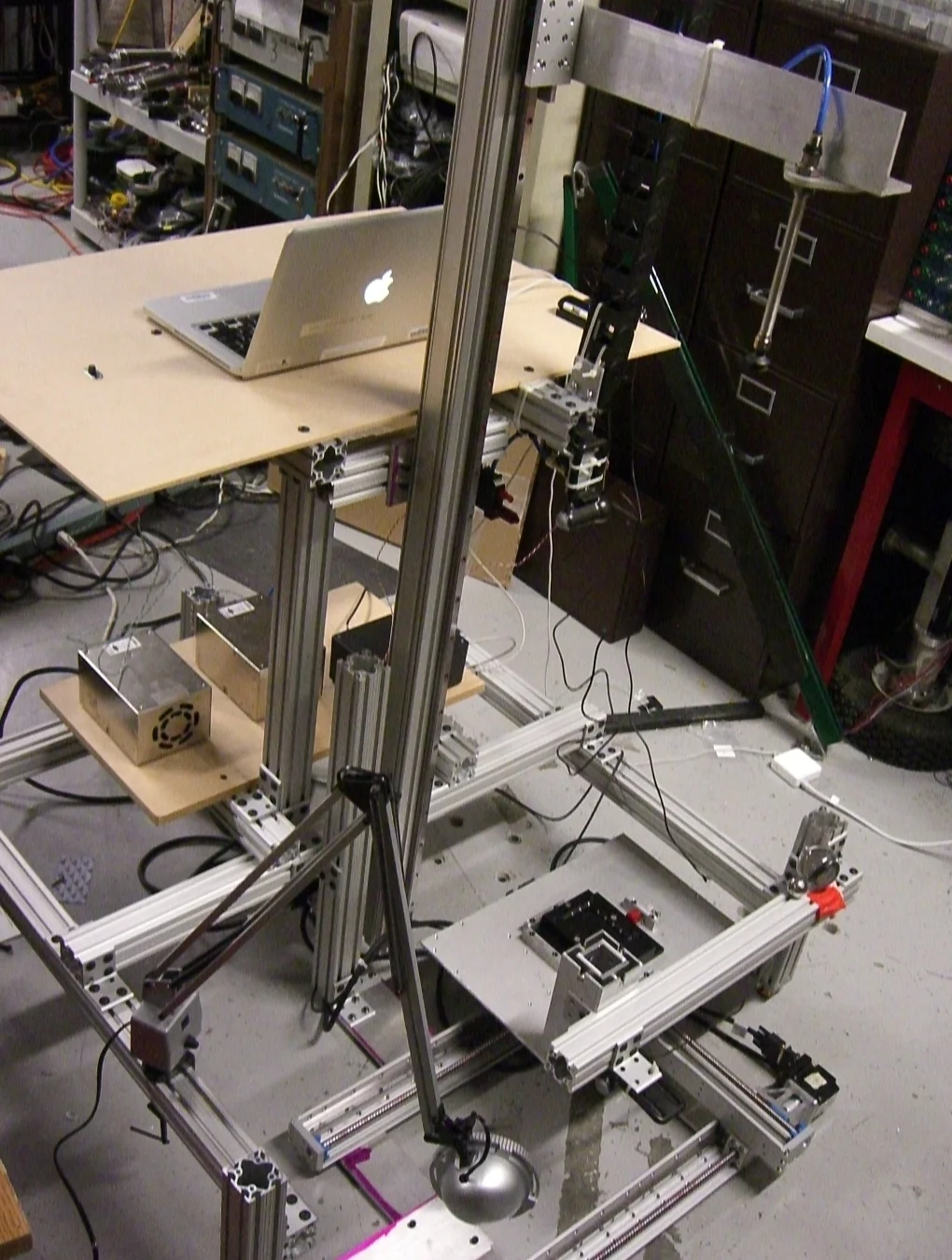

2009, Stanford University

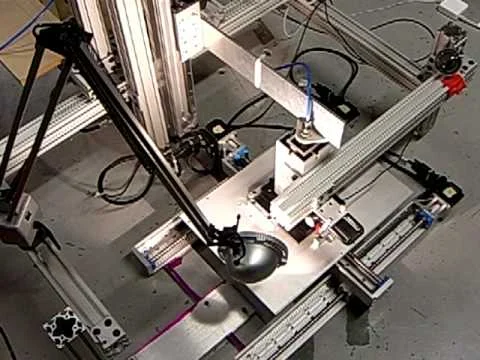

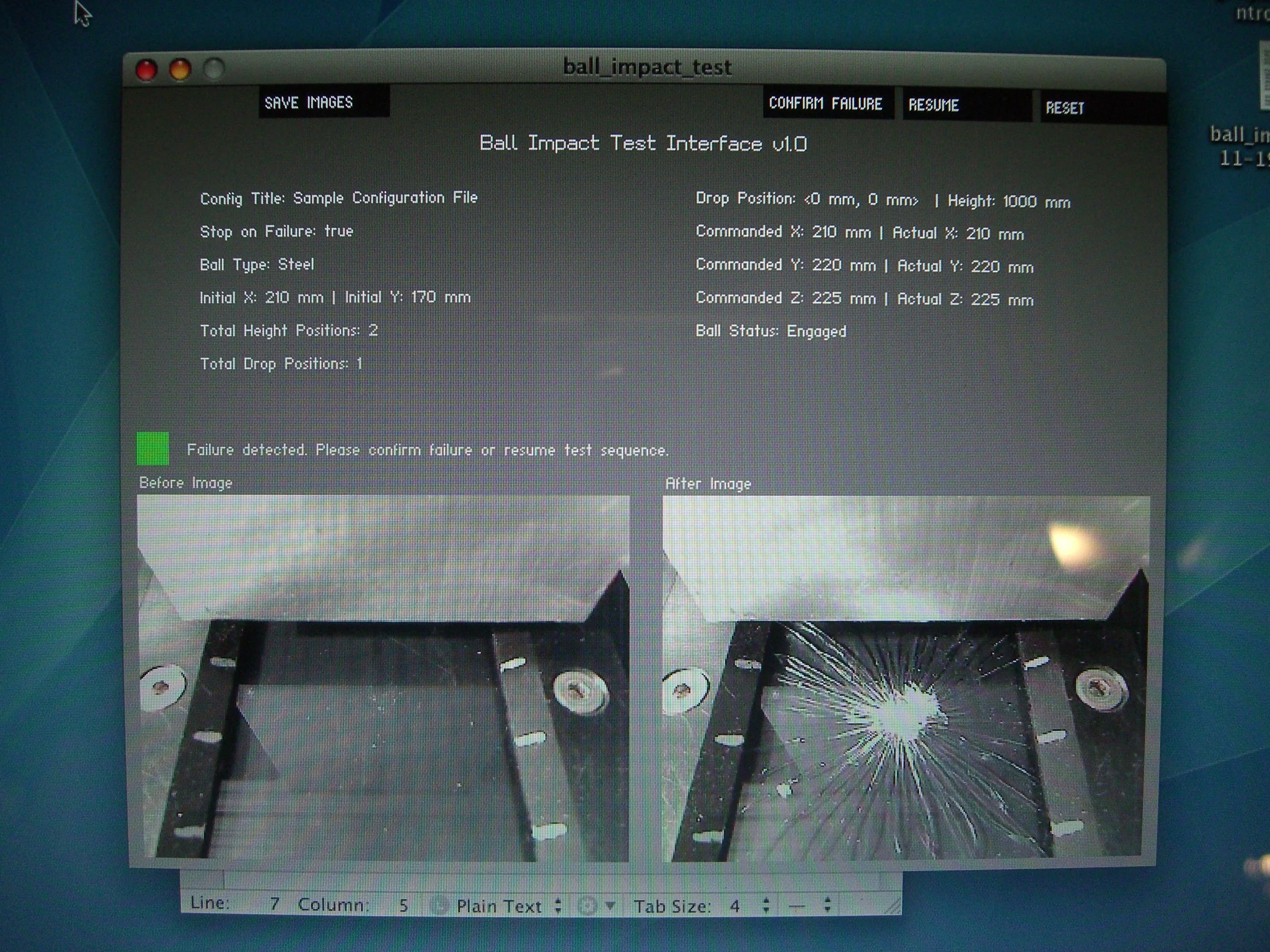

My team built this test rig for Apple, our corporate partner for ME 218D - Smart Product Design: Projects. We were tasked with automating iPhone screen impact testing. The test involved dropping steel and acrylic balls from varying heights onto different places on the screen. Previously, the test was done by hand.

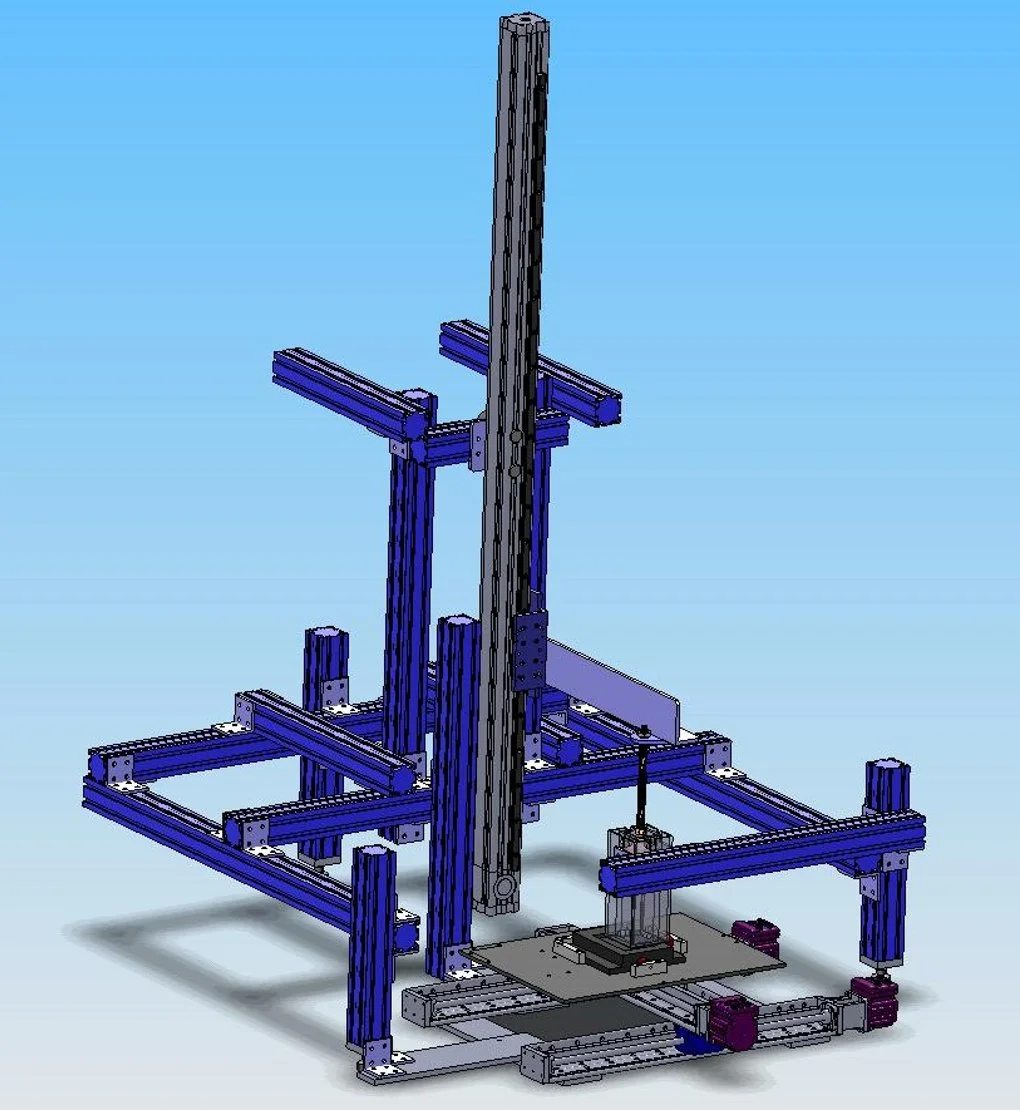

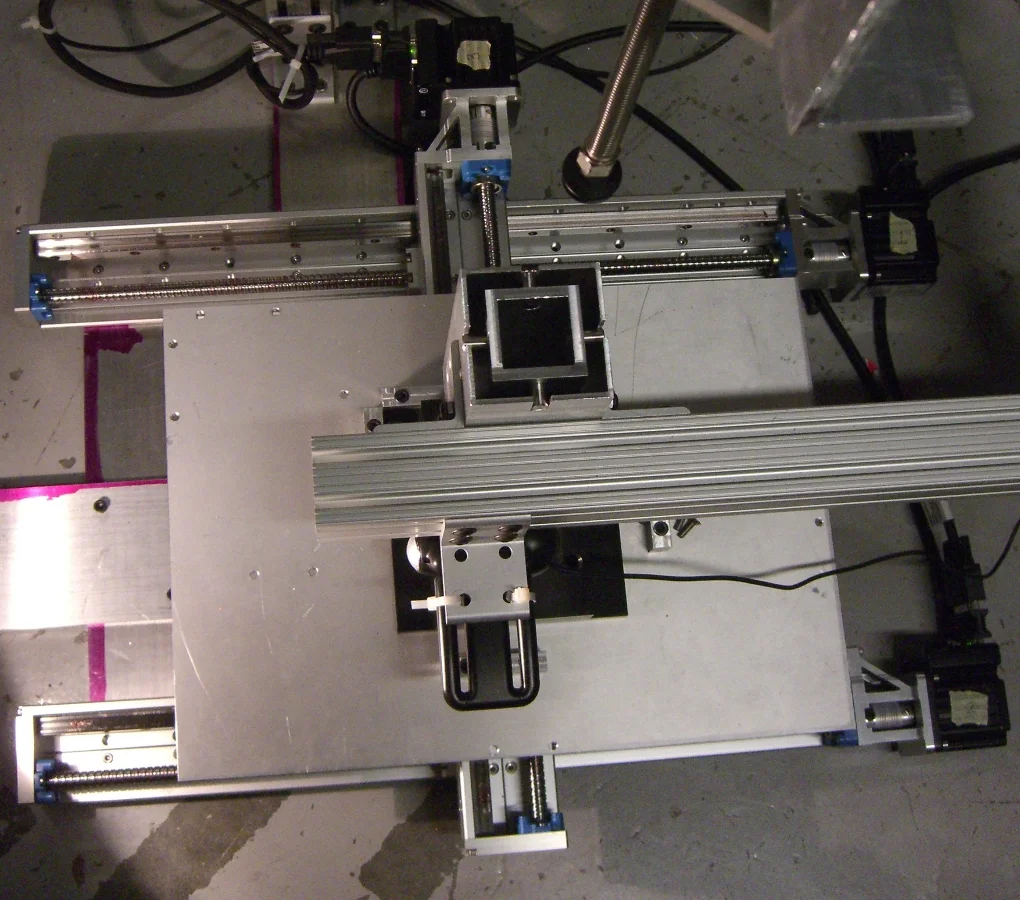

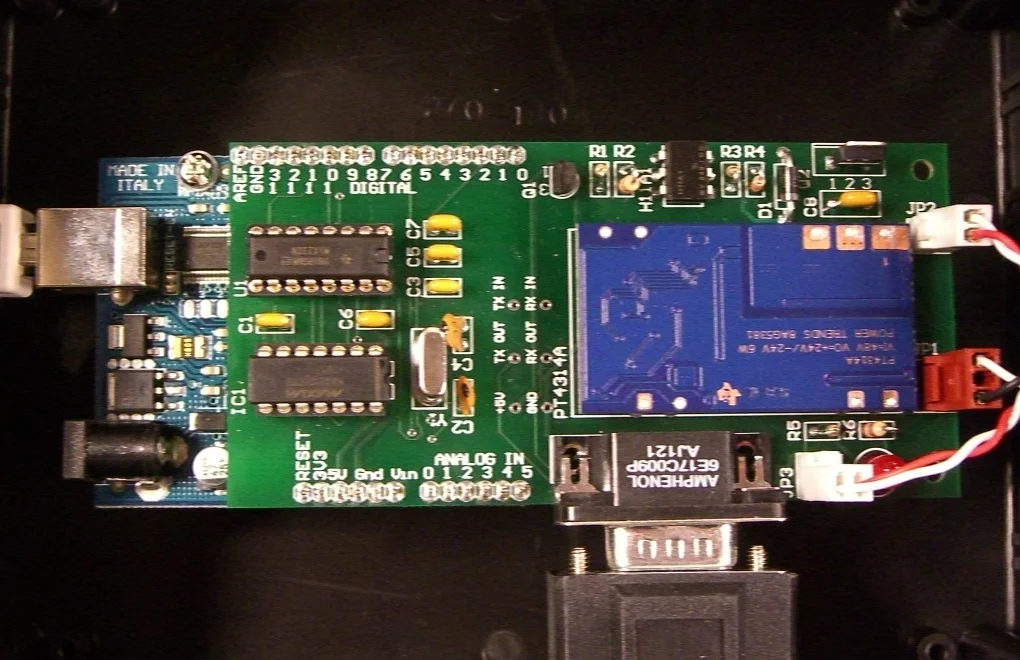

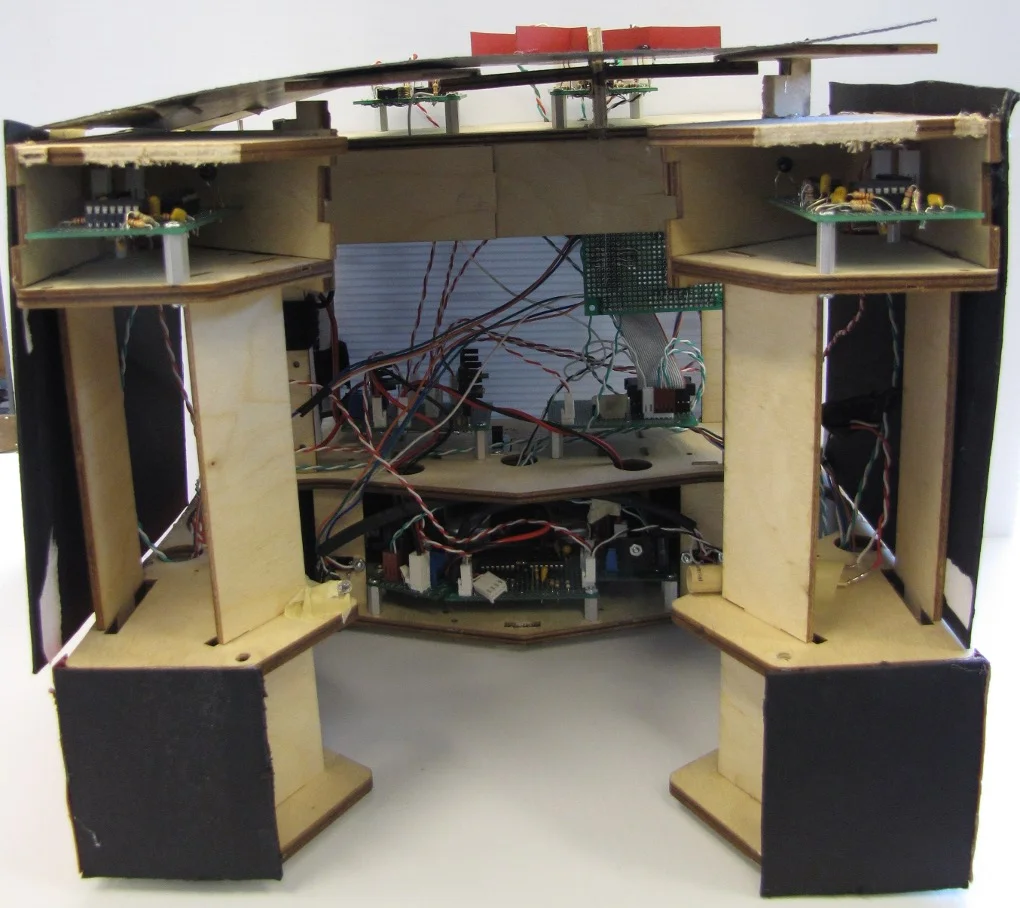

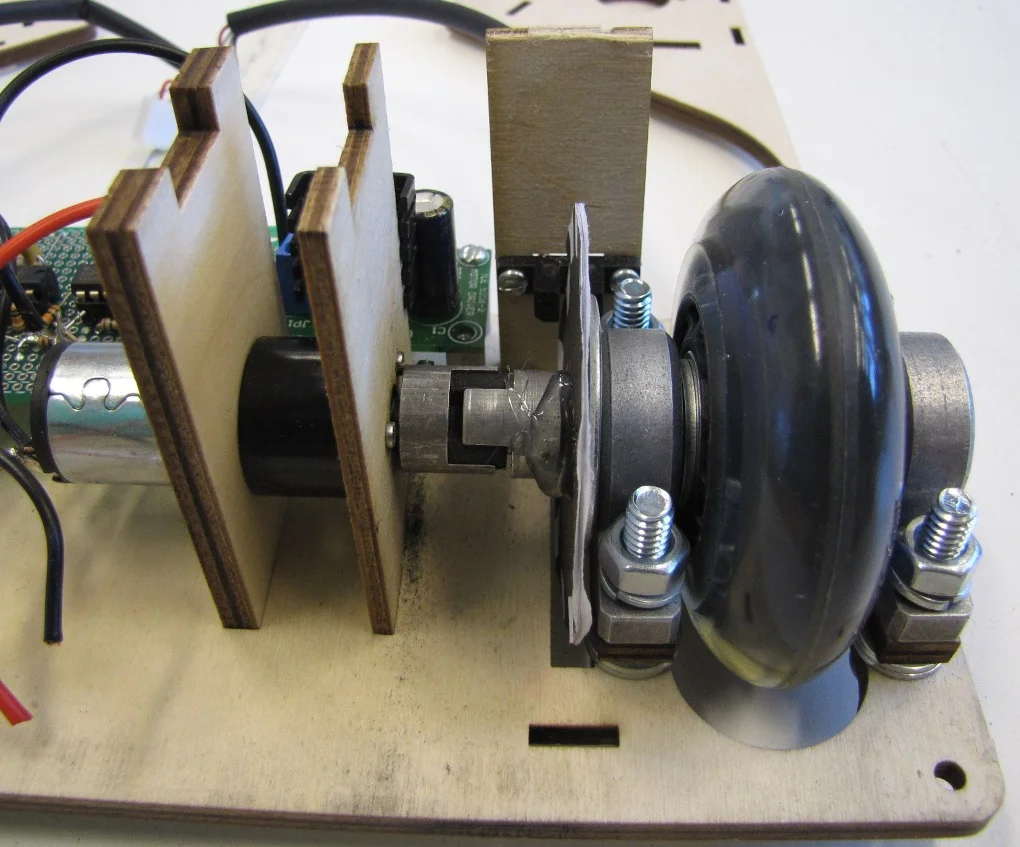

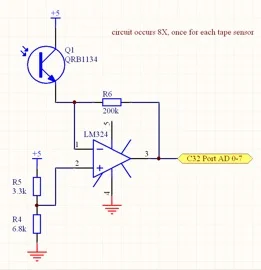

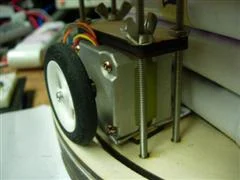

Our machine consisted of an XY motorized stage to position the screen, and a vertical linear actuator to lift the ball to the drop height. Suction from a vacuum system gripped the ball and released it at the proper height. A Processing script ran the tests from a MacBook. It controlled the screen position, ball height, and gripper suction through an Arduino with a custom PCB shield. The system used a webcam and machine vision to detect cracked screens during testing.

In addition to overall system design, I focused on the Arduino firmware and linear actuator control. The Animatics linear actuators we selected had position control that we commanded via RS232. The firmware received commands from the Processing executive, created a sequence of actuator actions, and transmitted them to the actuators. This process was coordinated by a state machine that could recover from faults, such as an actuator getting stuck.